Protection for Oil Transformer

Two types of devices are used to protect the power transformer: the ones that measure the voltages that affect the transformer via instrument transformers, and those that indicate the state of the physical quantities at the transformer.

4 Power Transformer Protection Devices Explained in Details

One example of the former is current-based differential protection, and the latter oil temperature monitoring.

Protective Devices //

Here are some protection devices that are typically included in power transformer deliveries

1. Buchholz (Gas) Relay

Buchholz protection is an electrical fault detector that detects electrical faults in oil-immersed Transformers. The Buchholz (gas relay) is located in the piping connecting the transformer main tank to the oil conservator. For reliable operation, the conservator pipe should be slightly inclined.

There is often a bypass pipe that allows the Buchholz relay to be taken out of service.

Buchholz gas relay installed

Buchholz protection is an extremely sensitive and fast fault detector. It does not depend on the number of transformer windings or tap changer position. The dedicated Buchholz relay is available for tap changers that are of the on-tank (container type) design. It has its own oil container with an oil conservator.

Buchholz relay principal construction

If a minor error occurs...

It is assumed that the transformer has a minor fault. Minor faults can produce gases that are produced at the top of the transformer. The gas bubbles will then travel up the piping and reach the conservator. The Buchholz protection will then be sealed with the gas bubbles.

This means that the gas replaces oil in the casing. The oil level drops, and the float (F), follows. A mercury switch is then tilted to close an alarm circuit.

If a major error occurs...

A major fault within the transformer is also possible. It could be between phases, earth, or windings. These faults can quickly produce large quantities of gas (more than 50 cm3/(KWS),) and oil vapour, which cannot escape.

These create a high-pressure buildup and displace oil. This causes a rapid flow of oil from the transformer to the conservatory. The vane (V), responds to high oil or gas flow in the conduit to the conservator. The mercury switch is used to close a trip circuit in this instance. The location of the fault current and its magnitude will determine the operating time of the trip contacts.

Gas accumulator relays also provide a long-term accumulation for gasses that are produced by overheating various parts of the insulation and transformer conductor. This prevents significant damage from occurring by detecting fault sources early.

Buchholz relay typical view with flanges on each side for pipe connections

The transformer's first service may be affected by air trapped between the windings. This could cause unnecessary alarm signals. Vacuum treatment is used to remove air from power transformers during oiling.

The gas that is accumulated without the treatment will be, naturally, air. This can be confirmed by ensuring it is not inflammable.

Buchholz relay technical articles //

Many power transformers that have an on-tank tap changer feature pressure protection for the separate oil compartment. This protects the tap changer oil compartment from sudden pressure increases.

2. Relay for pressure

The piston will move to control the switches contacts if the pressure on the piston is greater than the spring's counterforce. The switching unit's microswitch is enclosed in a hermetically sealed container and nitrogen gas pressurized.

The frangible disc is the most common form of pressure relief device. A heavy internal fault causes a surge in oil, which bursts the disc and allows oil to flow quickly. Limiting the pressure rise and relieving the pressure will prevent an explosive rupture of the tank and the subsequent fire.

If desired, the separate oil container for tap changers can be fitted with a pressure relief mechanism.

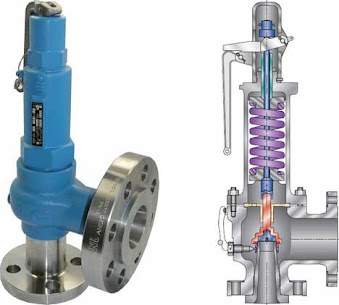

A pressure relief device is constructed in principle

You can attach the pressure relief device to a contact unit(s), which will provide a signal for circuit break(s) tripping circuits.

Pressure relief device with contact units

The frangible disk has a drawback in that oil left in the tank after rupture is exposed to the air. The pressure relief valve is a better option. It opens to allow oil to be released if pressure exceeds a pre-adjusted limit.

This spring-controlled valve is capable of operating within a few milliseconds if the abnormal pressure exceeds a certain level. It can also provide quick tripping if suitable contacts are installed. As soon as the internal pressure drops below a critical level, the valve will close automatically.

3. Oil Level Monitor Device

Many transformers have an oil conservator (expansion tank). The monitor usually has two alarm contacts. The one for maximum oil level alarm is the contact for alarm, while the other is for minimum oil alarm.

An oil level monitor device in its typical setting

The top-oil thermometer is equipped with a liquid thermometer bulb that is located in a pouch at the top of each transformer. The thermometer measures top-oil temperature. One to four contacts can be found on the top-oil thermometer. These contacts are sequentially closed at successively higher temperatures.

Below is an illustration of a capillary top-oil thermometer. The bulb is located in a "pocket", which is surrounded by oil. Through a capillary tube, the bulb is connected to a measuring bellow within the main unit. The indicator is moved by the bellow through mechanical linkages. This results in operation at predetermined temperatures.

Capillary top-oil temperature measuring device

In particular, the top-oil temperature can be significantly lower than the winding temperature. The top-oil thermometer does not provide overheating protection.

If the policy regarding transformers' loss in life allows, however, tripping on the top-oil temperature might be acceptable. This allows for direct monitoring of the oil temperature in order to avoid it reaching the flash temperature.

4. Capillary type winding thermometer

The winding thermometer captures the temperature at the end of each winding. Similar to the earlier method, the top-oil temperature can be measured using a similar technique. A current signal proportional to the loading current in winding is used to expand the measurement.

The current signal is obtained from the current transformer within the bushing of this particular winding. This current flows to the resistor element of the main unit. The current flows through the resistor, heating it up. This heats up and causes the measurement below to heat up. It then produces an increase in indicator movement.

Mounted on the side of a power transformer are top-oil and winding thermometer mains units

Temperature bias is proportional to the resistance of an electric heating element (resistor).

The heat run results provide data that can be used to adjust resistance and temperature bias. The difference in the hot-spot temperature from the top-oil temperature should be the bias. The heating time of the pocket should be the same as that of the winding.

If the bias is equal or greater than the temperature difference, the temperature sensor measures the winding temperature.

Four contacts are used to activate fans or pumps for forced cool. The two lowest levels can also be used to trigger an alarm. The fourth level is used to trip load breakers, de-energize the transformer, or both.

If a power transformer has a top-oil thermometer or winding thermometer attached, the latter usually handles the forced cooling control.

No comments:

Post a Comment