What is Engineering

Engineering is that the software of technology and math to resolve problems. Engineers discover how matters paintings and to discover sensible makes use of for scientific discoveries. Scientists and inventors frequently get the credit score for improvements that strengthen the human condition, however, it’s engineers who're instrumental in making the one's improvements to be had to the planet.

What is electric engineering?

Electrical engineering is that the layout, construction and maintenance of electrical manipulate structures, equipment and system. Some EE worries are also located in mechanical and engineering.

The time period EE frequently consists of electronics engineering. While electric engineers particularly specialize in large-scale manufacturing and distribution of electrical electricity, electronics engineers are involved with smaller digital circuits and from time to time additionally paintings with computer systems and different cutting-edge technologies. However, any undergraduate path will encompass factors of each electric and electronics engineering.

Electrical engineers upload delivery networks, lighting, heating, ventilation, carry structures, electricity era and distribution, renewable strength, production and construction. you’ll intricate task plans, estimate task timescales and costs, control the paintings of technicians and craftspeople, take a look at installations, examine records and ensure that fitness and protection policies are met.

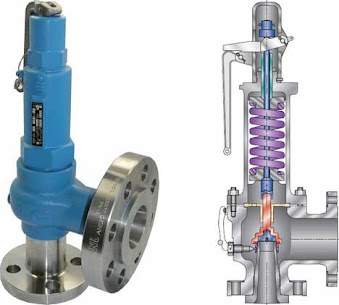

What is mechanical engineering

mechanical engineering is that the have a look at gadgets and structures in motion. As such, the world of engineering touches honestly each thing of the latest life, which include the physical body, a tremendously complicated machine.

The position of an engineer is to require a product from an idea to the marketplace. To accomplish this, the engineer needs to be prepared to decide the forces and thermal surroundings that a product, its parts, or its subsystems will encounter; layout them for functionality, aesthetics, and durability; and decide the most effective production technique so that you can make certain operation without failure.

Mechanical engineers play key roles for the duration of a large choice of industries which include automobile, aerospace, biotechnology, computer systems, electronics, microelectromechanical structures, strength conversion, robotics and automation, and production. The American Society of Mechanical Engineers (ASME) presently lists 36 technical divisions, from superior strength structures and aerospace engineering to solid-waste engineering and fabric engineering.

The breadth of the engineering field lets in college students a variety of professional alternatives past the industries indexed above. irrespective of the real direction they envision for themselves, engineering training empowers college students with creative abilities to style an interesting product or system; analytical equipment to understand their layout goals; the electricity to conquer all constraints; and consequently the teamwork had to fashion, market, and bring a system. These treasured abilities are frequently implemented to release careers in lots of different fields, like medicine, law, consulting, management, banking, and finance.

What is Information Technology Engineering?

IT engineers are hired in lots of diverse industries to make, install, or troubleshoot era and software program programs. If you’d want to turn out to be an IT engineer, you may in all likelihood want at the least a baccalaureate. Job increase for the duration of this discipline is expected to be lots quicker than common inside the coming decade.

IT engineers follow their technical expertise to resolve a variety of technological challenges. they’ll additionally create new technologies, which include the occasion of networking answers and software program programs. A baccalaureate is typically required, and an instructional diploma can also be essential for an extra superior position.

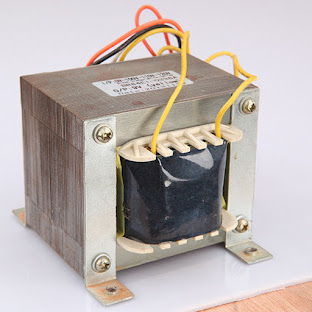

What is electronics engineering?

Electronics engineering can be a department of engineering that offers the planning, fabrication, and operation of circuits, digital gadgets, and structures.

Electronic engineering or electronics engineering can be a form of engineering associated with digital circuits, gadgets and consequently the system and structures that use them.

Electronic engineering utilises a variety of diverse forms of digital additives from the extra conventional analogue additives via to virtual digital additives, microprocessors and microcontrollers additionally as programmable good judgment gadgets.

What is Automobile Engineering?

The automobile or automobile era has won reputation and significance ever on the grounds that motors successful for transporting passengers has been hip. Now the way to the last climb of car element producers and car industries, there’s a brilliant call for Automobile Engineers. Automobile Engineering alias automobile era or Vehicle Engineering is one a few of the principal hard careers inside the discipline of engineering with a terrific scope.

This department offers the designing, developing, production, trying out and repairing and servicing motors like cars, trucks, motorcycles, scooters etc & the associated sub Engineering structures. For the proper combo of manufacturing and designing motors, Automobile Engineering makes use of the functions of diverse factors of Engineering like mechanical, electric, digital, software program and protection engineering.

What is electronics and telecommunication engineering?

Electronics Engineering is one of the maximum essential and maximum state-of-the-art branches of engineering. it’s made us be had a system like Television, Radio, computer systems, telephones, etc. Electronics functions a prime position in enhancing productiveness in industries like oil, strength, agriculture than many different essential sectors of the economy.

An electronics engineer works in organizations to fashion, fabricate, produce, take a look at, and supervise the production of complicated merchandise and structures.